Τα cookies μας βοηθούν να παρέχουμε τις υπηρεσίες μας. Με τη χρήση των υπηρεσιών μας, συμφωνείτε με τη χρήση των cookies.

Φιλτράρισμα με τιμή

Flatbed Cut & Crease Systems

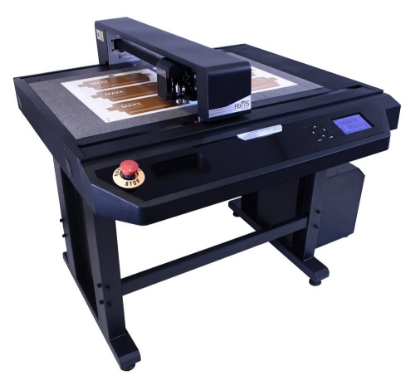

Intec ColorCut FB1175 Flatbed Cutter (4up x Tabloid Extra sheets)

High Speed - Dual Tool Intec Flatbed Cutter - Maximum Media Area: 800mm x 1100mm (31.4"" x 43.3"")

Maximum Effective Contour Cutting Area: 750mm x 1095mm (29.5""x 43"")

Dual Tool cutting head with Creasing tool & cutting blade.

3 Quality Modes (Fast / Standard / High Quality) / Max. Speed: 1,200mm per second

Max. Creasing Pressure 1.5Kg/1500g (3.3Lbs ) / Max. Cut Pressure 1.2Kg /1200g (2.4Lbs )

Vision3 CCD Camera Registration and QR Code Job Recognition (with auto find job for mixed jobs on table)

Includes 1000W Vacuum Suction system, 1 x Green Cutting Mat, 1 x Grey Felt Cutting Mat

5" LCD Touch Panel Display and Control system.

Software: Intec ColorCut Professional Software (2 User) - With Remote job library and productivity features.

Includes Stand, and Accoustic Housing for Vacuum Fan. plus includes Accoustic Muffler Accessories Pack included: 1 x 30° Blade, 1 x 45° Blade, 1 x 60° Blade, 3 x 45° Circlip Knife, 3 x 60° Circlip Knife, Dual ended creasing tool (Narrow crease/Wide crease) , Calibration pen tool and Wi-Fi Dongle for Wi-fi connection.

Maximum Effective Contour Cutting Area: 750mm x 1095mm (29.5""x 43"")

Dual Tool cutting head with Creasing tool & cutting blade.

3 Quality Modes (Fast / Standard / High Quality) / Max. Speed: 1,200mm per second

Max. Creasing Pressure 1.5Kg/1500g (3.3Lbs ) / Max. Cut Pressure 1.2Kg /1200g (2.4Lbs )

Vision3 CCD Camera Registration and QR Code Job Recognition (with auto find job for mixed jobs on table)

Includes 1000W Vacuum Suction system, 1 x Green Cutting Mat, 1 x Grey Felt Cutting Mat

5" LCD Touch Panel Display and Control system.

Software: Intec ColorCut Professional Software (2 User) - With Remote job library and productivity features.

Includes Stand, and Accoustic Housing for Vacuum Fan. plus includes Accoustic Muffler Accessories Pack included: 1 x 30° Blade, 1 x 45° Blade, 1 x 60° Blade, 3 x 45° Circlip Knife, 3 x 60° Circlip Knife, Dual ended creasing tool (Narrow crease/Wide crease) , Calibration pen tool and Wi-Fi Dongle for Wi-fi connection.

Intec ColorCut FB1180T Flatbed Cutter (4up x Tabloid Extra sheets)

High Speed - Quad Tool (2 +2T) Intec Flatbed Cutter - Maximum Media Area: 31.4"" x 43.3"" (800mm x 1100mm)

Maximum Effective Contour Cutting Area: 26.77""x 39.3"" ( 680mm x 1000m )

Quad Tool cutting head with 4 tool positions built in a 2 + 2 configuration.

- Enabling 2 Creasing tools (Ball & Tangential Crease Wheel)

- 2 cutting tools (Drag/Swivel for high speed thinner substrates (up to 600-800 micron), Tangential for N/F/E fluted board

- 2 Tools can be used in at a time, users can chose which tool combination they wish to apply.

3 Quality Modes (Fast / Standard / High Quality) / Max. Speed: 1,200mm per second

Max. Creasing Pressure 1900g/1.9Kg (4.2Lbs) / Max. Cut Pressure 1900g/1.9Kg (4.2Lbs ).

Vision3 CCD Camera Registration and QR Code Job Recognition (with auto find job for mixed jobs on table)

Includes 1000W Vacuum Suction system 1 x Green Cutting Mat, 1 x Grey Felt Cutting Mat

New 7" Screen with Live Video displayed on the 7"" Info-Control LCD screen, New Controller - NO WIRES operation mode.

Software: ColorCut Professional v.5 Software (2 User) - With Remote job library and productivity features.

Includes Stand, and Accoustic Housing for Vacuum Fan. plus includes Accoustic Muffler

Accessories Pack included:

1 x 30° Blade, 1 x 45° Blade, 1 x 60° Blade, 3 x 45° Circlip Knife, 3 x 60° Circlip Knife,

2 x Ball creasing tool, (1 x Wide, Narrow ),

1x Tangential Blade Holder, 3 x 45° 5mm Tangential Cutting blades.

Plus: 1 x Tangential Creasing Wheel holder, + 2 Creasing Wheels , 1 x 0.5mm wide creasing wheel for Fluted board, 1 x 0.3mm Wide creasing wheel for FBB, SBB and SBS Digital box Boards , Calibration pen tool.

Maximum Effective Contour Cutting Area: 26.77""x 39.3"" ( 680mm x 1000m )

Quad Tool cutting head with 4 tool positions built in a 2 + 2 configuration.

- Enabling 2 Creasing tools (Ball & Tangential Crease Wheel)

- 2 cutting tools (Drag/Swivel for high speed thinner substrates (up to 600-800 micron), Tangential for N/F/E fluted board

- 2 Tools can be used in at a time, users can chose which tool combination they wish to apply.

3 Quality Modes (Fast / Standard / High Quality) / Max. Speed: 1,200mm per second

Max. Creasing Pressure 1900g/1.9Kg (4.2Lbs) / Max. Cut Pressure 1900g/1.9Kg (4.2Lbs ).

Vision3 CCD Camera Registration and QR Code Job Recognition (with auto find job for mixed jobs on table)

Includes 1000W Vacuum Suction system 1 x Green Cutting Mat, 1 x Grey Felt Cutting Mat

New 7" Screen with Live Video displayed on the 7"" Info-Control LCD screen, New Controller - NO WIRES operation mode.

Software: ColorCut Professional v.5 Software (2 User) - With Remote job library and productivity features.

Includes Stand, and Accoustic Housing for Vacuum Fan. plus includes Accoustic Muffler

Accessories Pack included:

1 x 30° Blade, 1 x 45° Blade, 1 x 60° Blade, 3 x 45° Circlip Knife, 3 x 60° Circlip Knife,

2 x Ball creasing tool, (1 x Wide, Narrow ),

1x Tangential Blade Holder, 3 x 45° 5mm Tangential Cutting blades.

Plus: 1 x Tangential Creasing Wheel holder, + 2 Creasing Wheels , 1 x 0.5mm wide creasing wheel for Fluted board, 1 x 0.3mm Wide creasing wheel for FBB, SBB and SBS Digital box Boards , Calibration pen tool.

Intec ColorCut FB575 Flatbed Cutter (SRA3)

Dual Tool Intec Flatbed Cutter - Maximum Media Area: .350mm x 520mm (13.7"" x 20.4"")

Maximum Effective Contour Cutting Area: 330mm x 488mm (13"" x 19.2"").

Dual Tool cutting head with Creasing tool & cutting blade.

Max. Speed: 600mm per second / Max thickness 600 micron.

Max. Cutting & Creasing Pressure 960g (2.1Lbs ) each tool

Includes 400W Vacuum Suction system 1 x Green Cutting Mat, 1 x Grey Felt Cutting Mat

Software: Intec ColorCut Professional Software (2 User) - With Remote job library and productivity features

Includes Stand, and Housing for Vacuum Fan. (Accoustic Muffler optional)

Accessories Pack included: 1 x 30° Blade, 1 x 45° Blade, 1 x 60° Blade, 3 x 45° Circlip Knife, 3 x 60° Circlip Knife, Dual ended creasing tool (Narrow crease/Wide crease), Calibration pen tool.

Maximum Effective Contour Cutting Area: 330mm x 488mm (13"" x 19.2"").

Dual Tool cutting head with Creasing tool & cutting blade.

Max. Speed: 600mm per second / Max thickness 600 micron.

Max. Cutting & Creasing Pressure 960g (2.1Lbs ) each tool

Includes 400W Vacuum Suction system 1 x Green Cutting Mat, 1 x Grey Felt Cutting Mat

Software: Intec ColorCut Professional Software (2 User) - With Remote job library and productivity features

Includes Stand, and Housing for Vacuum Fan. (Accoustic Muffler optional)

Accessories Pack included: 1 x 30° Blade, 1 x 45° Blade, 1 x 60° Blade, 3 x 45° Circlip Knife, 3 x 60° Circlip Knife, Dual ended creasing tool (Narrow crease/Wide crease), Calibration pen tool.

Intec ColorCut FB580 Flatbed Cutter (SRA3)

Dual Tool Flatbed Cutter

Dual Tool:

1. Passive cutting blade

2. Creasing ball tool

- Maximum Media Area: 13.7" x 20.4" (350mm x 520mm)., Maximum Effective Contour Cutting Area: 13" x 19.2" ( 330mm x 488mm).

- Max. Cutting & Creasing Pressure 1,200g (2.1Lbs ) each tool

- Vision3 CCD Camera Sensor for fast sheet recognition and job retrieval.

- Max. Speed: 1200mm per second / Max thickness 600 micron

- Includes 400W Vacuum Suction system 1 x Green Cutting Mat, 1 x Grey Felt Cutting Mat

- 7" Front mounted Articulating enhanced ColorCut GUI Info-Control panel, Stores up to 1million jobs *Using optional USB Storage.

- Includes Stand, and Housing for Vacuum Fan. (Acoustic Muffler optional)

Software: ColorCut Professional v5 Software (2 User) - With Remote job library and productivity features, plus1yr ColorCut Software Maintenance Plan.

Accessories Pack included: 1 x 30° Blade, 1 x 45° Blade, 1 x 60° Blade, 3 x 45° Circlip Knife, 3 x 60° Circlip Knife, Dual ended creasing tool (Narrow crease/Wide crease), Calibration pen tool.

Dual Tool:

1. Passive cutting blade

2. Creasing ball tool

- Maximum Media Area: 13.7" x 20.4" (350mm x 520mm)., Maximum Effective Contour Cutting Area: 13" x 19.2" ( 330mm x 488mm).

- Max. Cutting & Creasing Pressure 1,200g (2.1Lbs ) each tool

- Vision3 CCD Camera Sensor for fast sheet recognition and job retrieval.

- Max. Speed: 1200mm per second / Max thickness 600 micron

- Includes 400W Vacuum Suction system 1 x Green Cutting Mat, 1 x Grey Felt Cutting Mat

- 7" Front mounted Articulating enhanced ColorCut GUI Info-Control panel, Stores up to 1million jobs *Using optional USB Storage.

- Includes Stand, and Housing for Vacuum Fan. (Acoustic Muffler optional)

Software: ColorCut Professional v5 Software (2 User) - With Remote job library and productivity features, plus1yr ColorCut Software Maintenance Plan.

Accessories Pack included: 1 x 30° Blade, 1 x 45° Blade, 1 x 60° Blade, 3 x 45° Circlip Knife, 3 x 60° Circlip Knife, Dual ended creasing tool (Narrow crease/Wide crease), Calibration pen tool.

Intec ColorCut FB775 Flatbed Cutter (2up Tabloid Extra)

High Speed - Dual Tool Intec Flatbed Cutter - Maximum Media Area: 580mm x 800mm ( 22.8"" x 31.4"").

Maximum Effective Contour Cutting Area: 480mm x 715mm (18.9""x 28.1"" )

Dual Tool cutting head with Creasing tool & cutting blade.

3 Quality Modes (Fast / Standard / High Quality) / Max. Speed: 1,200mm per second

Max. Creasing Pressure 1.5Kg/1500g (3.3Lbs) / Max. Cut Pressure 1.2Kg /1200g ( 2.4Lbs ).

Vision3 CCD Camera Registration and QR Code Job Recognition (with auto find job for mixed jobs on table)

Includes 750W Vacuum Suction system, 1 x Green Cutting Mat, 1 x Grey Felt Cutting Mat

5" LCD Touch Panel Display and Control system.

Software: Intec ColorCut Professional Software (2 User) - With Remote job library and productivity features.

Includes Stand, and Accoustic Housing for Vacuum Fan. plus includes Accoustic Muffler Accessories Pack included: 1 x 30° Blade, 1 x 45° Blade, 1 x 60° Blade, 3 x 45° Circlip Knife, 3 x 60° Circlip Knife, Dual ended creasing tool (Narrow crease/Wide crease) , Calibration pen tool and Wi-Fi Dongle for Wi-fi connection.

Maximum Effective Contour Cutting Area: 480mm x 715mm (18.9""x 28.1"" )

Dual Tool cutting head with Creasing tool & cutting blade.

3 Quality Modes (Fast / Standard / High Quality) / Max. Speed: 1,200mm per second

Max. Creasing Pressure 1.5Kg/1500g (3.3Lbs) / Max. Cut Pressure 1.2Kg /1200g ( 2.4Lbs ).

Vision3 CCD Camera Registration and QR Code Job Recognition (with auto find job for mixed jobs on table)

Includes 750W Vacuum Suction system, 1 x Green Cutting Mat, 1 x Grey Felt Cutting Mat

5" LCD Touch Panel Display and Control system.

Software: Intec ColorCut Professional Software (2 User) - With Remote job library and productivity features.

Includes Stand, and Accoustic Housing for Vacuum Fan. plus includes Accoustic Muffler Accessories Pack included: 1 x 30° Blade, 1 x 45° Blade, 1 x 60° Blade, 3 x 45° Circlip Knife, 3 x 60° Circlip Knife, Dual ended creasing tool (Narrow crease/Wide crease) , Calibration pen tool and Wi-Fi Dongle for Wi-fi connection.

Intec ColorCut FB780T Flatbed Cutter (2up Tabloid Extra)

Dual Tool Flatbed Cutter - with 1 Active (Tangential) Tool & 1 Independent Passive (Drag/Contour) Tool.

- Maximum Media Area: 13.7" x 20.4" (350mm x 520mm)., Maximum Effective Contour Cutting Area: 13" x 19.2" ( 330mm x 488mm).

- Tool 1: Creasing Wheel (Tangential Tool) (Tool can be changed to optional Tangential Cutting tool), Tool 2: Passive (Drag) Cutting Tool

- Max pressure 2.5Kg / Active Creasing Wheel (Tangential Tool), 1Kg/1000g Passive Cutting Tool / Max speed: 1200mm/s.

- Vision3 High Res CCD Camera with Instant QR Code Job recognition

- 7" Front mounted Articulating enhanced ColorCut GUI Info-Control panel, Stores up to 1million jobs *Using optional USB Storage.

- Includes 750W Vacuum Suction system 1 x Green Cutting Mat, 1 x Grey Felt Cutting Mat

- Includes Stand, and Acoustic Housing for Vacuum Fan. plus includes Acoustic Muffler

Software: ColorCut Professional v5 Software (2 User) - With Remote job library and productivity features plus1yr ColorCut Software Maintenance Plan.

Accessories Pack included: 1 x 30° Blade, 1 x 45° Blade, 1 x 60° Blade, 3 x 45° Circlip Knife, 3 x 60° Circlip Knife, Magnetic mounting - Narrow Creasing Wheel (Tangential Tool), Calibration pen tool

- Maximum Media Area: 13.7" x 20.4" (350mm x 520mm)., Maximum Effective Contour Cutting Area: 13" x 19.2" ( 330mm x 488mm).

- Tool 1: Creasing Wheel (Tangential Tool) (Tool can be changed to optional Tangential Cutting tool), Tool 2: Passive (Drag) Cutting Tool

- Max pressure 2.5Kg / Active Creasing Wheel (Tangential Tool), 1Kg/1000g Passive Cutting Tool / Max speed: 1200mm/s.

- Vision3 High Res CCD Camera with Instant QR Code Job recognition

- 7" Front mounted Articulating enhanced ColorCut GUI Info-Control panel, Stores up to 1million jobs *Using optional USB Storage.

- Includes 750W Vacuum Suction system 1 x Green Cutting Mat, 1 x Grey Felt Cutting Mat

- Includes Stand, and Acoustic Housing for Vacuum Fan. plus includes Acoustic Muffler

Software: ColorCut Professional v5 Software (2 User) - With Remote job library and productivity features plus1yr ColorCut Software Maintenance Plan.

Accessories Pack included: 1 x 30° Blade, 1 x 45° Blade, 1 x 60° Blade, 3 x 45° Circlip Knife, 3 x 60° Circlip Knife, Magnetic mounting - Narrow Creasing Wheel (Tangential Tool), Calibration pen tool

Intec ColorCut LC600

Label Sheet Feeder & Cutting System

Single Tool cutter with Touch panel LCD control & Vision3 High Res CCD Camera, with Instant QR Code Job recognition

- Max speed: 960mm/s, Max pressure 750g.

- Includes sheet feeder for up to 200 sheets.

- Includes Stand

Single Tool cutter with Touch panel LCD control & Vision3 High Res CCD Camera, with Instant QR Code Job recognition

- Max speed: 960mm/s, Max pressure 750g.

- Includes sheet feeder for up to 200 sheets.

- Includes Stand

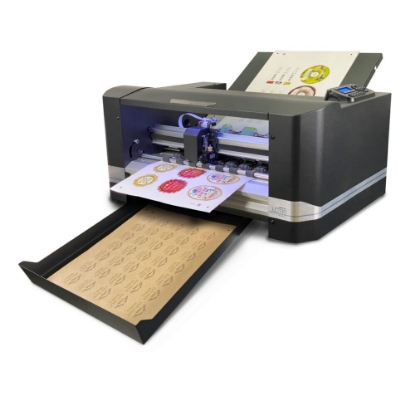

Intec ColorCut LC700 Pro

Premium Autofeed Label Cutting System

- Premium, Servo motor Technology Label cutter with Single Tool cutting head for professional applications

- 7" Touch panel LCD control & Vision3 High Res CCD Camera, with Instant QR Code Job recognition

- Max speed: 1060mm/s, Max pressure 750g.

- Includes sheetfeeder for up to 250 sheets.

- Patent pending "HELD MODE", stores up to 1million jobs on cutter for unattended use *Using USB Storage.

- Ergonomic, space saving retractable exit tray. Compact and mobile footprint / includes easily maneuverable stand.

- Includes ColorCut Pro 5 and Industry 4.0 Compliant log output, plus1yr ColorCut Software Maintenance Plan.

- Premium, Servo motor Technology Label cutter with Single Tool cutting head for professional applications

- 7" Touch panel LCD control & Vision3 High Res CCD Camera, with Instant QR Code Job recognition

- Max speed: 1060mm/s, Max pressure 750g.

- Includes sheetfeeder for up to 250 sheets.

- Patent pending "HELD MODE", stores up to 1million jobs on cutter for unattended use *Using USB Storage.

- Ergonomic, space saving retractable exit tray. Compact and mobile footprint / includes easily maneuverable stand.

- Includes ColorCut Pro 5 and Industry 4.0 Compliant log output, plus1yr ColorCut Software Maintenance Plan.

Intec ColorCut LCF700 Pro - Roll to Roll

Modular, Label Roll to Roll Finisher Frame system for LC700 series of cutters.

Full Roll to Roll modular housing frame for LC700 Pro series of cutters, Upgrades LC700 Pro to a full roll to roll cutter.

- 1 Input Label Roll Mandrel, supporting 150mm - 330mm wide media (Outer Diameter max 350mm)

- 1 input Laminating Roll Mandrel for easy release laminates (Gloss / Matt / Antibac)

- 6 Slitting knives for up to 7 Rolls from the single master roll.

- 1 Output Waste Matrix Madrel (Waste label frame removing roller/ system)

- Auto Tracking Control - Controls the label Web (Adjusts slitting based on lateral movement during a run)

Full Roll to Roll modular housing frame for LC700 Pro series of cutters, Upgrades LC700 Pro to a full roll to roll cutter.

- 1 Input Label Roll Mandrel, supporting 150mm - 330mm wide media (Outer Diameter max 350mm)

- 1 input Laminating Roll Mandrel for easy release laminates (Gloss / Matt / Antibac)

- 6 Slitting knives for up to 7 Rolls from the single master roll.

- 1 Output Waste Matrix Madrel (Waste label frame removing roller/ system)

- Auto Tracking Control - Controls the label Web (Adjusts slitting based on lateral movement during a run)

INTEC LC330 Label Cutter

Entry Level Autofeed Label Cutting System

Low cost desktop, Single Tool cutter with 2 line matrix LCD panel and touch key control

- Vision3 base CCD Camera, with Instant QR Code Job recognition

- Premium Stepper Motor controller. Max speed: 800mm/s, Max pressure 500g.

- Includes sheetfeeder for up to 120 sheets, and attachable exit tray.

- Uses ColorCut Pro 5 Lite (Compatible with the ColorCut Pro series of cutters), plus 1yr ColorCut Software Maintenance Agreement

Low cost desktop, Single Tool cutter with 2 line matrix LCD panel and touch key control

- Vision3 base CCD Camera, with Instant QR Code Job recognition

- Premium Stepper Motor controller. Max speed: 800mm/s, Max pressure 500g.

- Includes sheetfeeder for up to 120 sheets, and attachable exit tray.

- Uses ColorCut Pro 5 Lite (Compatible with the ColorCut Pro series of cutters), plus 1yr ColorCut Software Maintenance Agreement

Intec SC7000 Pro

The SC7000 Pro-T combine ultra-reliable feeding with an instant job retrieval system and high-speed cutting and tangential creasing

- Includes high capacity, advanced Vacuum Belt - Auto-Sheet feeder (up to 15Kgs of media / 1000 sheets)

- Dual Tool Carriage 1 Active Creasing (Tangential Tool) and 1 Passive (Contour/Drag) Tool

- Max pressure 2.5Kg / Active Creasing Wheel (Tangential Tool), 900g Passive Cutting Tool / Max speed: 1060mm/s.

- Max media size: 340 x 710mm

- Eff ective contour cutting area: 330 x 700mm

- Media handling: A4 (210 x 297mm), A3 (297 × 420mm), A3+ (330 × 485mm), SRA3 (320 × 450mm) and custom sizes

- Custom sized media: Media width (min-max): 180mm x 340mm / Media length (min-max): 279mm x 710mm

- Vision3 High Res CCD Camera with Instant QR Code Job recognition

- 7" Front mounted Articulating enhanced ColorCut GUI Info-Control panel, Stores up to 1million jobs *Using optional USB Storage.

- Max sheet width 340mm, Max Sheet length 710mm, Front Sheet extension for Reduced tags to hold elements

- Includes ColorCut Pro 5 and Industry 4.0 Compliant log output, plus1yr ColorCut Software Maintenance Agreement.

- Ergonomic, space saving retractable exit tray. Compact and mobile footprint / Easily maneuverable stand.

- Includes high capacity, advanced Vacuum Belt - Auto-Sheet feeder (up to 15Kgs of media / 1000 sheets)

- Dual Tool Carriage 1 Active Creasing (Tangential Tool) and 1 Passive (Contour/Drag) Tool

- Max pressure 2.5Kg / Active Creasing Wheel (Tangential Tool), 900g Passive Cutting Tool / Max speed: 1060mm/s.

- Max media size: 340 x 710mm

- Eff ective contour cutting area: 330 x 700mm

- Media handling: A4 (210 x 297mm), A3 (297 × 420mm), A3+ (330 × 485mm), SRA3 (320 × 450mm) and custom sizes

- Custom sized media: Media width (min-max): 180mm x 340mm / Media length (min-max): 279mm x 710mm

- Vision3 High Res CCD Camera with Instant QR Code Job recognition

- 7" Front mounted Articulating enhanced ColorCut GUI Info-Control panel, Stores up to 1million jobs *Using optional USB Storage.

- Max sheet width 340mm, Max Sheet length 710mm, Front Sheet extension for Reduced tags to hold elements

- Includes ColorCut Pro 5 and Industry 4.0 Compliant log output, plus1yr ColorCut Software Maintenance Agreement.

- Ergonomic, space saving retractable exit tray. Compact and mobile footprint / Easily maneuverable stand.

Intec SC7000 Pro XL

Extra Large Automated Vacuum Belt Feed - Auto Sheet Feeder & Cutting System

- Includes high capacity, advanced Vacuum Belt - Auto-Sheet feeder (up to 15Kgs of media / 1000 sheets)

- Dual Tool Carriage 1 Active Creasing (Tangential Tool) and 1 Passive (Contour/Drag) Tool

- Max pressure 2.5Kg / Active Creasing Wheel (Tangential Tool), 900g Passive Cutting Tool / Max speed: 1060mm/s.

- Max Media Handling: 550mm X 745mm.

- Effective contour cutting area: 510 x 700mm

- Vision3 High Res CCD Camera with Instant QR Code Job recognition

- 7" Front mounted Articulating enhanced ColorCut GUI Info-Control panel, Stores up to 1million jobs *Using optional USB Storage.

Front Sheet extension for Reduced tags to hold elements

- Includes ColorCut Pro 5 and Industry 4.0 Compliant log output, plus1yr ColorCut Software Maintenance Agreement.

- Ergonomic, space saving retractable exit tray. Compact and mobile footprint / Easily maneuverable stand.

- Includes high capacity, advanced Vacuum Belt - Auto-Sheet feeder (up to 15Kgs of media / 1000 sheets)

- Dual Tool Carriage 1 Active Creasing (Tangential Tool) and 1 Passive (Contour/Drag) Tool

- Max pressure 2.5Kg / Active Creasing Wheel (Tangential Tool), 900g Passive Cutting Tool / Max speed: 1060mm/s.

- Max Media Handling: 550mm X 745mm.

- Effective contour cutting area: 510 x 700mm

- Vision3 High Res CCD Camera with Instant QR Code Job recognition

- 7" Front mounted Articulating enhanced ColorCut GUI Info-Control panel, Stores up to 1million jobs *Using optional USB Storage.

Front Sheet extension for Reduced tags to hold elements

- Includes ColorCut Pro 5 and Industry 4.0 Compliant log output, plus1yr ColorCut Software Maintenance Agreement.

- Ergonomic, space saving retractable exit tray. Compact and mobile footprint / Easily maneuverable stand.

Intec ColorCut FB9000 Pro - AutoSheet Feeding Flatbed System

FB9000 Pro - Dual Tool Conveyor belt flatbed cutter with Auto Sheet feeder and exit tray

Maximum sheet size (Manual): 550mm x 800mm (21.6"" x 31.5"")/ (Autofeed): 483mm x 720mm(19"" x 28.3"")

Maximum Effective Contour Cutting Area (Manual) : 495mm x 735mm / (AutoFeed): 480 x 700 mm (18.9"" x 27.5"" )

Dual Tool cutting head with creasing tool & cutting blade, with Advanced CCD Vision3 Registration Camera

3 Quality Modes (Fast / Standard / High Quality) / Maximum Speed: 1,2000mm per second

Max. Creasing Pressure 1.5Kg/1500g (3.3Lbs ) / Max. Cut Pressure 2.4Lbs (1.2Kg /1200g)

Includes 750W - 2 Zone Vacuum suction system With Conveyor Belt & superior underlay Cutting Mat

Software: Intec ColorCut Professional Software (2 User)

Exit Tray and Accoustic Housing for Vacuum Fan. Accoustic Silencer/Muffler

Vacuum Auto-Sheet feed system with integrated air separation system for 220mm stack height ( 2,500 sheets)

Enables automated operation of continuous delivery of media to cutting conveyor.

Max media size for auto sheet delivery is:483mm x 720mm (19"" x 28.3"" ).

System includes high capacity air compressor, with all required couplings.

9 Blade accessories pack included: 1 x 30° Blade, 1 x 45° Blade, 1 x 60° Blade, 3 x 45° Circlip Knife, 3 x 60° Circlip Knife, Dual ended creasing tool (Narrow crease/Wide crease), Calibration pen tool.

Maximum sheet size (Manual): 550mm x 800mm (21.6"" x 31.5"")/ (Autofeed): 483mm x 720mm(19"" x 28.3"")

Maximum Effective Contour Cutting Area (Manual) : 495mm x 735mm / (AutoFeed): 480 x 700 mm (18.9"" x 27.5"" )

Dual Tool cutting head with creasing tool & cutting blade, with Advanced CCD Vision3 Registration Camera

3 Quality Modes (Fast / Standard / High Quality) / Maximum Speed: 1,2000mm per second

Max. Creasing Pressure 1.5Kg/1500g (3.3Lbs ) / Max. Cut Pressure 2.4Lbs (1.2Kg /1200g)

Includes 750W - 2 Zone Vacuum suction system With Conveyor Belt & superior underlay Cutting Mat

Software: Intec ColorCut Professional Software (2 User)

Exit Tray and Accoustic Housing for Vacuum Fan. Accoustic Silencer/Muffler

Vacuum Auto-Sheet feed system with integrated air separation system for 220mm stack height ( 2,500 sheets)

Enables automated operation of continuous delivery of media to cutting conveyor.

Max media size for auto sheet delivery is:483mm x 720mm (19"" x 28.3"" ).

System includes high capacity air compressor, with all required couplings.

9 Blade accessories pack included: 1 x 30° Blade, 1 x 45° Blade, 1 x 60° Blade, 3 x 45° Circlip Knife, 3 x 60° Circlip Knife, Dual ended creasing tool (Narrow crease/Wide crease), Calibration pen tool.

Intec ColorCut FB9500 Pro - AutoSheet feeding Flatbed System

Active Wheel Creasing, Passive cutting Automated flatbed cutter with Auto-Sheet feeder

FB9500 Cutting Table

- Dual Tool Carriage 1 Active Creasing (Tangential Tool) and 1 Passive (Contour/Drag) Tool

- Max pressure 2.5Kg / Active Creasing Wheel (Tangential Tool), 1,300g Passive Cutting Tool

- Maximum sheet (Manual): 21.6" x 31.5" (550mm x 800mm)/ (Autofeed): 20" x 28.3" (500mm x 720mm)

- Vision3 High Res CCD Camera with Instant QR Code Job recognition

- Advanced CCD Vision3 Registration Camera reads QR codes to find your jobs

- 7" Front mounted Articulating enhanced ColorCut LCD Control panel, Stores up to 1million jobs *Using optional USB Storage.

- 3 Quality Modes (Fast / Standard / High Quality) / Maximum Speed: 1,2000mm per second

- Includes 750W - 2 Zone Vacuum suction system With Conveyor Belt & superior underlay Cutting Mat

- Includes ColorCut Pro 5 and Industry 4.0 Compliant log output, plus1yr ColorCut Software Maintenance Agreement.

- Exit Tray and Accoustic Housing for Vacuum Fan. Accoustic Silencer/Muffler

FB9500 Auto-Sheet feeder system - Enables automated operation of continuous delivery of media to cutting conveyor.

- Max media size for auto sheet delivery is:20" x 28.3" (500mm x 720mm).

- Integrated air separation system for 220mm stack height ( 2,500 sheets)

- Patented rear camera system, cuts sheets face down, scans marks on rear side to enable accurate cutting from the top.

System includes high capacity air compressor, with all required couplings.

Accessories pack included: Passive Blade Holder, 9 Blades - 1 x 30° Blade, 1 x 45° Blade, 1 x 60° Blade, 3 x 45° Circlip Knife, 3 x 60° Circlip Knife, Dual Ball creasing tools (Narrow crease/Wide crease) , Tangential Magnetic Narrow Creasing Wheel.

FB9500 Cutting Table

- Dual Tool Carriage 1 Active Creasing (Tangential Tool) and 1 Passive (Contour/Drag) Tool

- Max pressure 2.5Kg / Active Creasing Wheel (Tangential Tool), 1,300g Passive Cutting Tool

- Maximum sheet (Manual): 21.6" x 31.5" (550mm x 800mm)/ (Autofeed): 20" x 28.3" (500mm x 720mm)

- Vision3 High Res CCD Camera with Instant QR Code Job recognition

- Advanced CCD Vision3 Registration Camera reads QR codes to find your jobs

- 7" Front mounted Articulating enhanced ColorCut LCD Control panel, Stores up to 1million jobs *Using optional USB Storage.

- 3 Quality Modes (Fast / Standard / High Quality) / Maximum Speed: 1,2000mm per second

- Includes 750W - 2 Zone Vacuum suction system With Conveyor Belt & superior underlay Cutting Mat

- Includes ColorCut Pro 5 and Industry 4.0 Compliant log output, plus1yr ColorCut Software Maintenance Agreement.

- Exit Tray and Accoustic Housing for Vacuum Fan. Accoustic Silencer/Muffler

FB9500 Auto-Sheet feeder system - Enables automated operation of continuous delivery of media to cutting conveyor.

- Max media size for auto sheet delivery is:20" x 28.3" (500mm x 720mm).

- Integrated air separation system for 220mm stack height ( 2,500 sheets)

- Patented rear camera system, cuts sheets face down, scans marks on rear side to enable accurate cutting from the top.

System includes high capacity air compressor, with all required couplings.

Accessories pack included: Passive Blade Holder, 9 Blades - 1 x 30° Blade, 1 x 45° Blade, 1 x 60° Blade, 3 x 45° Circlip Knife, 3 x 60° Circlip Knife, Dual Ball creasing tools (Narrow crease/Wide crease) , Tangential Magnetic Narrow Creasing Wheel.

ColorCut Pro - Job Library Server Station

A dedicated ColorCut Server Station with powerful Quad Core Processor, 8GB Ram, 20" LCD screen and ergonomic Workstation stand.

Pre-installed with ColorCut Pro Production Studio software (Includes 2 ColorCut Pro 3 licenses) which accepts jobs from Mac or PC artwork computers on the same network providing an optimised ColorCut Job Library server for standalone production of your cutting jobs without interrupting your graphic designers.

Also includes ColorCut Pro TemplateMaker for unlimited Box Designs and ColorCut Job Library Manager for ultimate cut file control.

Pre-installed with ColorCut Pro Production Studio software (Includes 2 ColorCut Pro 3 licenses) which accepts jobs from Mac or PC artwork computers on the same network providing an optimised ColorCut Job Library server for standalone production of your cutting jobs without interrupting your graphic designers.

Also includes ColorCut Pro TemplateMaker for unlimited Box Designs and ColorCut Job Library Manager for ultimate cut file control.